The industry of medical devices thrives off innovation. To bring new concepts to life, is essential to find a reliable partner that can transform concepts into prototypes and eventually, high-quality components for production. Influx Labs steps in to fulfill this crucial job, providing a complete solution for medical device companies that want excellence in prototype manufacturing and CNC manufacturing.

Influx Labs: From Dream to Prototype: Medical Device Innovation Facilitated

Medical device companies often face a complex journey, from conception to market launch. Influx Labs understands the importance of effective prototype manufacturing in this process. They provide a friendly and supportive atmosphere that allows you to transform your creative ideas into prototypes that can be tested that allows you to make improvements and collect feedback before you commit to mass production.

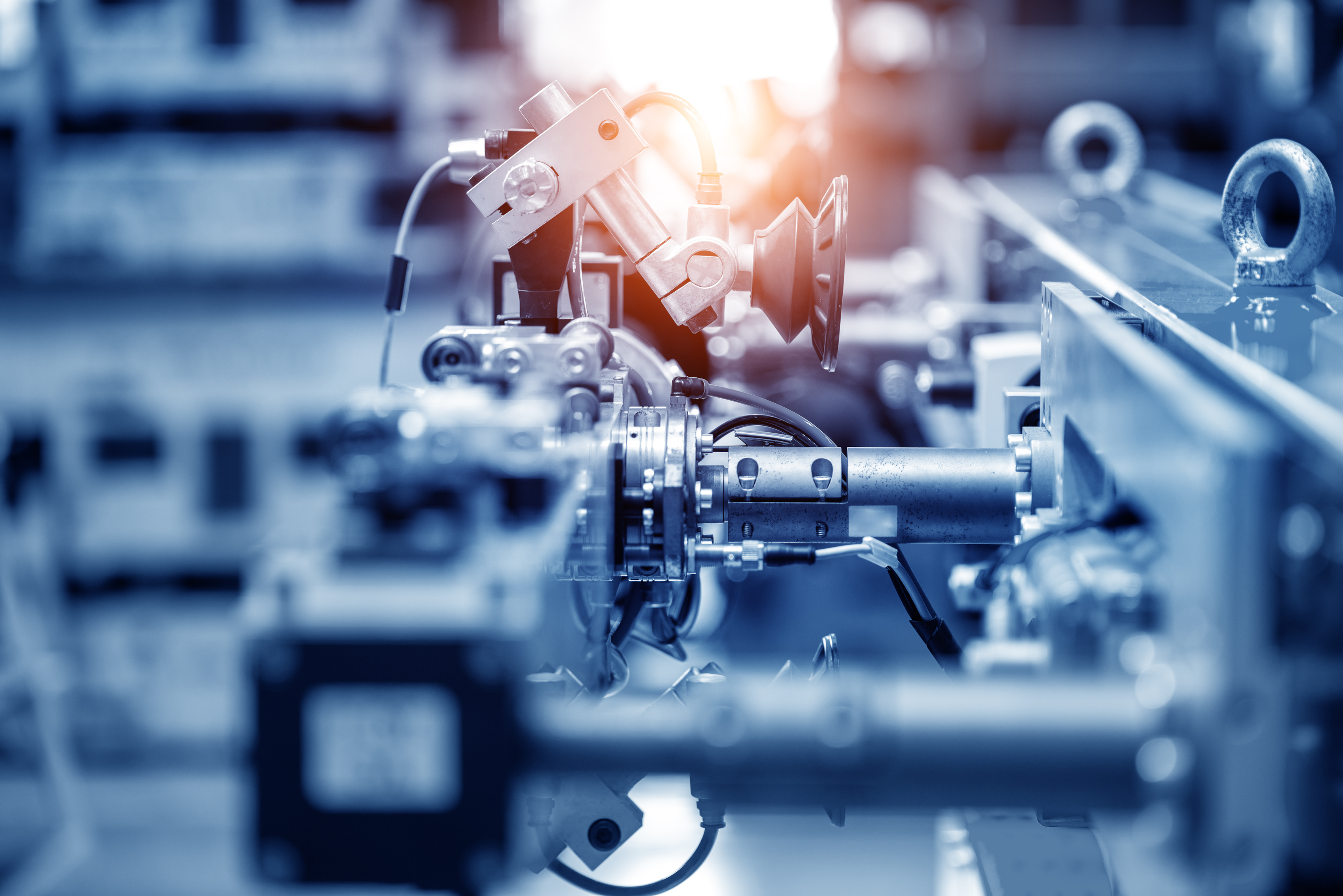

The power of Precision: Influx Labs’ Expertise in CNC Machining

Influx Labs’ core competency is their advanced CNC machining technology. Computer Numerical Control machining (CNC) utilizes computer-aided instruction to precisely control the cutting tools, which allows for highly precise and complex components. Influx Labs is able to make medical device prototypes as and production parts which meet the strictest medical device requirements.

The Next Step is Production Scaling

Influx Labs’ services extend beyond rapid prototyping. Their expertise in CNC-machining allows an effortless transition from prototypes to high quantity production runs. This reduces the need to seek out a separate manufacturing partner which streamlines the entire process and guaranteeing that the prototype is identical to the final product.

Certifications and traceability of the material A commitment to excellence

Influx Labs is aware of the crucial role quality plays in the world of medical devices. They follow a rigorous process with full traceability of all materials throughout their entire process. You’ll have complete transparency about the materials used to make your prototypes and the components that will be used in production. Influx Labs also offers material and finishing certificates on demand. This gives you peace of mind and helps you comply with stringent regulatory requirements.

Why should you select Influx Labs for your medical device needs?

Influx Labs stands out from other companies for prototypes and machining due to several reasons. What makes them an ideal partner for medical device development

Influx Labs is dedicated to the Medical Devices Industry. We recognize the unique requirements of this industry. They have the expertise and experience required to make medical-grade parts of top quality.

Precision Engineering: Their advanced CNC machining capabilities ensure consistent results and unparalleled accuracy which is essential to create efficient and durable medical devices.

Seamless transition: Influx Labs offers a one-stop shop for prototyping and production, thereby saving you time and money in finding different vendors.

Commitment To Quality: Influx Labs is committed to quality, right from material traceability to certifications. We will ensure that medical devices are in compliance with the highest standards.

Influx Labs – Accelerating your Medical Device Development Journey

Influx Labs’ expertise in prototyping and CNC machining helps medical device companies to bring fresh concepts to life faster and with greater efficiency. Influx Labs is a great partner as you are able to:

Reduced risk: Prototyping helps you identify possible issues early during the process of development which reduces risks that come with large-scale production.

Influx Labs’ streamlined prototyping and production process lets you bring your medical device faster to the market.

Improved Design Refinement : Physical prototypes permit complete testing and feedback from the users and allows you to refine your designs with more confidence.

Influx Labs can help you discover the full potential of speedy prototypes and high-precision CNC machines. Watch your innovative medical device concepts become a reality and contribute to shaping the future of health care.